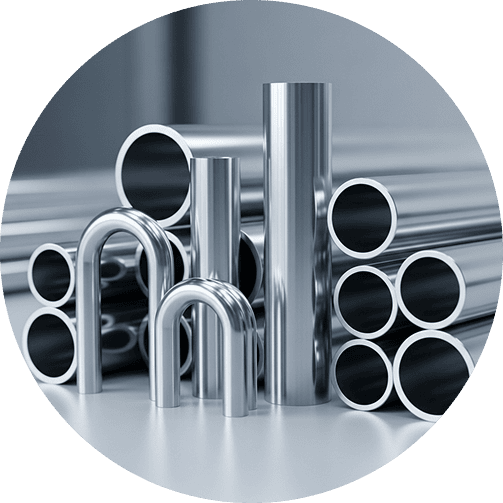

Stainless Steel U Tubes: Leading Manufacturer & Supplier

Stainless Steel "U" Tubes are an essential part of industries where strength, precision, and anti-rust quality are the cornerstones of successful operations. From power plants and chemical facilities to sectors like ornamental & hardware, furniture, sugar industries, textile machinery, and petroleum & gas, these tubes form the axial structure of heat transfer systems, enabling maximum efficiency even under high-pressure and temperature conditions. Engineered to support a wide spectrum of industrial applications, they play a crucial role in enhancing operational reliability and performance.

What are SS U-tubes and Where Are They Used?

Stainless steel U-tubes are either welded or seamless tubes that are bent in the form of a “U” in a way that there is maximum utilization of space with effective heat transfer. They are used in U-tube heat exchangers, economizers, condensers, and boiler loops, among many others. They can withstand high-pressure fluids, thermal cycling, and aggressive media, and therefore are a must-have for critical infrastructure applications.

Key Applications of Stainless Steel U-Tubes in Industry

- Power Generation Plants: Applied in U-tube heat exchangers, the tubes provide consistent cooling and condensing of steam in thermal power plants, nuclear power plants, and renewable power plants.

- Oil & Gas and Petrochemicals: They are resistant to aggressive chemicals and high pressure and are best suited for offshore platforms and refineries.

- HVAC Systems and Refrigeration: Stainless steel U-bend tubes assist in achieving the right heat exchange in industrial air conditioners.

- Pharmaceutical & Food Processing: Their clean properties make them ideal for industries where contamination-free processes are critical.

Grades of Stainless Steel Used in U Tube Manufacturing

At HMT, we manufacture U tubes using a wide variety of stainless steel materials to meet different mechanical and chemical requirements:

- Austenitic Grades: SS 304, SS 304L, SS 316, SS 316L, SS 321

- Heat-Resistant Grades: SS 347, SS 310

- Special Grades: Duplex stainless steel and custom alloys (available on request)

This versatility allows HMT to cater not only to standard applications but also to industries demanding alloy steel U-tube manufacturers for extreme environments.

Stainless Steel U Tube Manufacturing Process Explained

HMT U-tube production process is a combination of advanced technology and strict quality checks:

- Tube Selection: Premium stainless steel seamless or welded tubes are chosen based on customer specifications.

- Cold Drawing (if required): To achieve precision dimensions, tubes undergo cold drawing before bending.

- Precision Bending: Latest “U” bending machines are used for accurate shaping while preventing wall thinning.

- Heat Treatment: Solution annealing heat treatment after bending guarantees stress relief and enhanced corrosion resistance.

- Dimensional Inspection: Straightness, wall thickness, and bend radius of each Stainless Steel U Tube are inspected.

- Hydrostatic & Non-Destructive Testing: Leak-free operation is guaranteed in pressure tests, eddy current, and ultrasonic testing.

- Cleaning & Passivation: Tubes are pickled and cleaned to improve surface finish and eliminate any impurities.

Why Precision Matters in U Tube Manufacturing

In high-stakes industries, a single-dimensional variation can impact efficiency and safety. U-bend tubes manufacturers like HMT ensure:

- Exact bend radius and leg length tolerance

- Uniform wall thickness throughout the bent section

- Reliable performance under high-temperature cycling

- Extended product life, minimizing downtime and replacement costs

How to Choose the Right Stainless Steel U Tube Manufacturer

Selecting the right partner goes beyond price– it’s about expertise, credentials, and technical ability. A reliable stainless steel U tube manufacturer should provide:

- Global quality certifications (ISO, PED, etc.)

- Internal testing facilities for destructive and non-destructive tests

- Capacity to provide custom lengths, radii, and grades of material

- Ability to meet custom lengths, radii, and material grades

- Proven track record with EPC contractors, power plants, and OEMs

HMT meets all these requirements, making it one of the top U tube heat exchanger suppliers.

HMT: Trusted Stainless Steel U Tube Manufacturer & Supplier

With over four decades of engineering excellence, HMT is a pioneer in manufacturing stainless steel U bend tubes that meet stringent international standards.

Why industries trust HMT:

- Three modern manufacturing plants in Gujarat

- Advanced U-bending machines for precise, repeatable results

- Complete in-house testing, heat treatment, and finishing capabilities

- Capacity to handle bulk and customized orders for global delivery

SS U Tube Customization Options Offered by HMT

Every project is unique, and HMT delivers custom-engineered solutions:

- Bend Radii: Designed as per heat exchanger specifications

- Tube Lengths: Up to 12 meters straight, with precise U-bends

- Material Grades: From standard SS 304 to high-performance duplex alloys

- Surface Finish: Pickled, polished, or bright-annealed options

- Testing & Certification: Third-party inspection as per client requirements

Global Standards Followed in SS U Tube Production

HMT’s products comply with international norms such as:

- ASTM/ASME: A213, A269, A249

- EN/DIN Standards: DIN 17456, EN 10216

- NACE MR0175 for sour service applications

This ensures stainless steel U-tubes can be seamlessly integrated into global projects without additional modifications.

Packaging & Delivery Process for SS U Tubes

Safe delivery is critical for precision-engineered tubes. HMT’s packing standards include:

- Plastic end caps to prevent contamination

- Protective wrapping and wooden cases to avoid transit damage

- Bundles designed for easy handling during international shipping

- Clear labeling with grade, size, and heat number for traceability

Stainless Steel U Tube Price Factors & Market Trends

The cost of stainless steel U tubes depends on several factors:

- Material grade (e.g., SS 316 is more expensive than SS 304)

- Tube dimensions and wall thickness

- Order quantity and customization requirements

- Market trends in nickel and chromium pricing

- Testing, inspection, and certification levels

HMT offers competitive pricing while ensuring no compromise on quality, making them a preferred choice among stainless steel pipe suppliers and U-bend tube manufacturers worldwide.

Why HMT Stands Out Among SS U Tube Suppliers

- End-to-end manufacturing – from raw material to finished product

- Proven expertise in U-tube heat exchanger applications

- Global supply network with a strong track record in exports

- Commitment to sustainability through eco-friendly operations

- Trusted by leading EPC contractors, refineries, and power plants

Conclusion

Stainless steel U-tubes are not just materials, but a determining factor in the efficiency and security of today's industries. With cutting-edge infrastructure, quality checks with standards, and decades of experience, HMT continues to be a trendsetter as a reliable stainless steel U-tube manufacturer and supplier of U-tube heat exchangers.

When accuracy, performance, and dependability are paramount, choose HMT—where every curve represents strength, quality, and trust.