Page 8 - HeavyMetal

P. 8

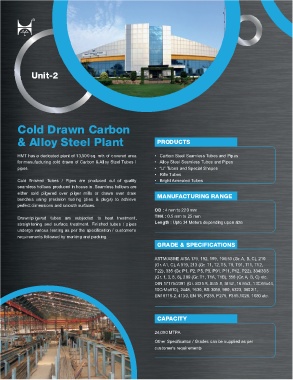

Unit-2

Cold Drawn Carbon

& Alloy Steel Plant PRODUCTS

HMT has a dedicated plant of 13,500 sq. mtr. of covered area • Carbon Steel Seamless Tubes and Pipes

for manufacturing cold drawn of Carbon & Alloy Steel Tubes / • Alloy Steel Seamless Tubes and Pipes

pipes. • “U” Tubes and Special Shapes

• Rifle Tubes

Cold finished Tubes / Pipes are produced out of quality • Bright Annealed Tubes

seamless hollows produced in house in. Seamless hollows are

either cold pilgered over pilger mills or drawn over draw MANUFACTURING RANGE

benches using precision tooling (dies & plugs) to achieve

perfect dimensions and smooth surfaces.

OD : 4 mm to 220 mm

Drawn/pilgered tubes are subjected to heat treatment, THK : 0.5 mm to 25 mm

straightening and surface treatment. Finished tubes / pipes Length : Upto 34 Meters depending upon size

undergo various testing as per the specification / customer’s

requirements followed by marking and packing.

GRADE & SPECIFICATIONS

ASTM/ASME A/SA 179, 192, 199, 106/53 (Gr. A, B, C), 210

(Gr. A1, C), A 519, 213 (Gr. T1, T2, T5, T9, T91, T11, T12,

T22), 335 (Gr. P1, P2, P5, P9, P91, P11, P12, P22), 334/333

(Gr. 1, 3, 8, 6), 209 (Gr. T1, T1A, T1B), 556 (Gr. A, B, C) etc.

DIN 17175/2391 (Gr. St35.8, St45.8, St 52, 16 Mo3, 13CrMo44,

10CrMo910), 2448, 1630, BS 3059, 980, 6323, 3602/1,

EN10716-2, 4130, EN 18, P235, P275, P355,1026, 1030 etc.

CAPACITY

24,000 MTPA

Other Specification / Grades can be supplied as per

customer's requirements